- Start Date

- 2024/08/06

- End Date

- 2024/08/09

- Event Details

-

Roadshow

Dates: 6 August 2024, 10:00 to 15:35 in Indonesia Time

Venue: Hotel Borobudur JakartaBootcamp

Dates: 7 to 9 August 2024Organizer: TOPCON POSITIONING ASIA CO., LTD., PT. SYNNEX METRODATA INDONESIA

- URL

- /content/topcon-pa/jp/en/events/2024/topcon-autodesk_roadshow-bootcamp_Indonesia.html

- Target

- _self

Mobile Mapping System Case Study

IP-S3 HD1

3D Measurements of Fishing Harbors with MMS Survey Boat!

Bring MMS to the Scene by Boat, Bicycle or Wagon with the Compact IP-S3 HD1

Mobile Mapping Systems (MMS) make it possible to take 3D measurements of wide areas in short amounts of time. MMS gained traction with the Geospatial Information Authority of Japan’s publishing of a provisional operation manual in 2012, but are still typically mounted on automobiles for mobility. Meanwhile, Kouwa Corporation, a general construction consulting company in Hachinohe City, Aomori Prefecture, took the unique approach of mounting the MMS IP-S3 HD1 onto vehicles other than automobiles. This is the story of their efforts.

Responding to Increasing Demand for 3D Measurements

“We have proactively worked toward 3D measurement ever since introducing the GLS-1500 3D laser scanner five years ago,” Kouwa Corporation Managing Director and Geospatial Information Department General Manager Motoyoshi Kikuchi said. Through numerous 3D jobs performed since then, the company has diligently amassed knowledge of handling point cloud data. Kikuchi said the company has received more orders for 3D measurement work in construction surveying as well as public surveying in recent years, which seems to indicate the high regard clients have for Kouwa’s experience. In response, the company added a GLS-2000 3D laser scanner last year, and has decided to start using the IP-S3 HD1, which makes it possible to acquire high-density point cloud data in a shorter time and over a broader range than laser scanners. This signifies a focus on the diffusion of “i-Construction”.

Introducing the IP-S3 HD1 Surveying Boat!

Kouwa’s most noteworthy application of the IP-S3 HD1 is in the surveying of a fishing harbor. They used the GLS-2000 to measure terrain, and a narrow multi-beam echo sounder to measure submarine topography, and they mounted the IP-S3 HD1 onto a surveying boat to measure breakwaters and wave-dissipating blocks. They used three sensors to render all aspects of the fishing harbor – terrain, structures and seafloor – in 3D.

“It is easy to measure terrain using 3D laser scanners,” Kouwa Corporation Sendai Branch Manager Representative Tsukasa Todome said regarding the details of the work. “It is also easy to measure the seafloor using echo sounder. The challenging part was rendering the condition of the breakwaters and the way the wave-dissipating blocks are stacked in detail in 3D. When you survey from land, you want to get as close as possible in order to minimize blind spots. Setting up 3D laser scanners on top of wave-dissipating blocks is too dangerous, but you cannot get complete measurements from the sides of steep breakwaters, either. That being the case, we thought to try taking measurements using the IP-S3 HD1 aboard a surveying boat.” Kouwa used three sensors to take 3D measurements in the field in a true “hybrid 3D measurement” approach. They used the 3D point cloud processing software MAGNET Collage to generate the data. MAGNET Collage software is used to process 3D point cloud data. The software processes data acquired from 3D laser scanners, UAV, MMS and other sensors at high speed to produce point clouds, which can then be generated to enable users to integrate and manipulate 3D point clouds. The company was able to smoothly generate data without any problems with coherence, which was a concern, and is very satisfied with the results. “As this is the first time we have ever mounted MMS on a boat, we cannot make sweeping comparisons to conventional methods,” Todome said. “However, I think this is an excellent technique because we were able to take measurements more quickly than expected, and also more safely because we did not have to go to dangerous places, and considering the excellence of the results, we can produce highly efficient, high-quality results.”

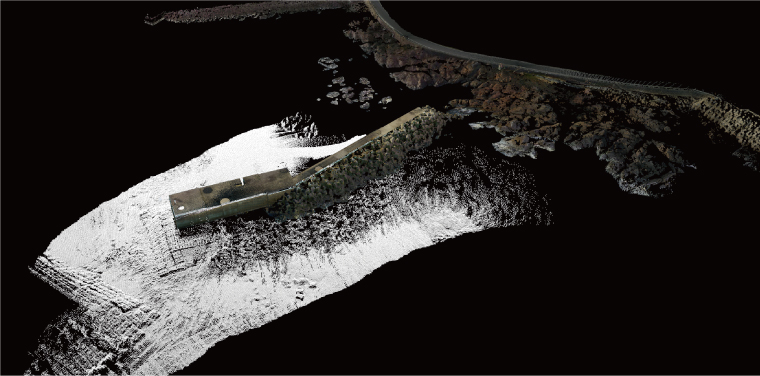

A fishing harbor and its environs rendered in 3D using point cloud data. MAGNET Collage was used to integrate data from the IP-S3 HD1, the GLS-2000 and an echo sounder.

A fishing harbor and its environs rendered in 3D using point cloud data. MAGNET Collage was used to integrate data from the IP-S3 HD1, the GLS-2000 and an echo sounder.

Compactness Provides Unprecedented Versatility

Before Kouwa decided to introduce the IP-S3 HD1, the company rigorously compared the MMS of various companies. “Throughout the comparison, our main focus was to see if we could develop and deploy a completely new application for MMS,” Kikuchi reflected. They discussed the matter internally, but also with professors from local universities and a wide range of others, and the last MMS standing was the IP-S3 HD1. The deciding factor was the excellent handling made possible by the compact, lightweight system. “We felt there was a range of applications beyond the general image of MMS as a technology to be paired with automobiles,” Kikuchi said. “We felt that we could mount the IP-S3 HD1 not only on surveying boat, but also on other types of vehicles.”

Kouwa provided one more example of using an MMS on a vehicle other than an automobile, this time using the IP-S3 HD1 to survey river embankments. “A considerable amount of time and effort were required to transport a 3D laser scanner over the total round-trip distance of 12 km [for this measurement],” Geospatial Information Department Spatial Measurement Group member Yuka Kawamata said. “Moreover, passenger walkways made up most of the survey area, so we could not use an automobile to enter the area. Therefore, I proposed that we take measurements by mounting the IP-S3 HD1 onto a pedal-assist electric bicycle with a trailer or a motorized wagon.” Although the work was estimated to take roughly two weeks using the conventional method, using the IP-S3 HD1 enabled the company to complete the work in roughly two hours. In terms of work time alone, the work was 40 times more efficient.

The ability to complete fieldwork quickly can reduce costs, which presents a major advantage to both clients and contractors. “I believe that the IP-S3 HD1 was the right choice by far,” Kikuchi said, quite satisfied with the performance.。

Left: The IP-S3 HD1 on a bicycle trailer. Center: On a motorized wagon. This makes it possible to use the IP-S3 HD1 in places where automobiles and motorcycles cannot enter. Height restrictions under bridges and elsewhere pose no problems. Right: Of course, the IP-S3 HD1 can be mounted on an automobile. The company uses different combinations of UAV, the GLS-2000 and the IP-S3 HD1 to suit various conditions at development worksites, captures everything in 3D, and includes the data in the deliverables along with the viewer.

Left: The IP-S3 HD1 on a bicycle trailer. Center: On a motorized wagon. This makes it possible to use the IP-S3 HD1 in places where automobiles and motorcycles cannot enter. Height restrictions under bridges and elsewhere pose no problems. Right: Of course, the IP-S3 HD1 can be mounted on an automobile. The company uses different combinations of UAV, the GLS-2000 and the IP-S3 HD1 to suit various conditions at development worksites, captures everything in 3D, and includes the data in the deliverables along with the viewer.

Promoting the Use of 3D Data Expands Business

Kouwa is already using UAV to perform aerial photogrammetry, and now has all the equipment it needs to acquire 3D point cloud data thanks to the introduction of the IP-S3 HD1. The company has begun to use different combinations of 3D laser scanners, UAV and MMS to measure initial and finished dimensions at “i-Construction” worksites.

“In the future, we intend to use this technology not only for construction measurement and to measure present conditions, but also in surveying work for maintenance, for example, to survey roads, buildings, properties and structures,” Kikuchi said. To further promote the effective use of 3D point cloud data, the company has started including 3D point cloud data in conjunction with viewing software along with conventional deliverables. Visualization provided by 3D data seems highly regarded by clients as well.

Perhaps this signals a major change in 3D measurement.

* “i-Construction” is…

Ministry of Land, Infrastructure, Transport and Tourism (MLIT) in Japan has been promoting “i-Construction”, that the Japanese construction companies shall utilize 3D data in all the procedure of construction work to increase its productivity dramatically, generated by not only the conventional equipment such as Total Stations and GNSS receivers but also Drones, 3D Laser Scanners, and ICT Construction Machineries. “i-Construction” is a registered trademark of the National Institute for Land and Infrastructure Management, MLIT.

The Kouwa Corporation employees quoted in this story. From the left, Managing Director and Geospatial Information Department General Manager Motoyoshi Kikuchi, Sendai Branch Manager Representative Tsukasa Todome, and Geospatial Information Department Spatial Measurement Group member Yuka Kawamata

The Kouwa Corporation employees quoted in this story. From the left, Managing Director and Geospatial Information Department General Manager Motoyoshi Kikuchi, Sendai Branch Manager Representative Tsukasa Todome, and Geospatial Information Department Spatial Measurement Group member Yuka Kawamata

COMPANY:Kouwa Corporation

URL:http://www.kouwa-k.co.jp/

TOPCON PRODUCT:

Mobile Mapping System IP-S3 HD1

Related Item

News

Events

- Start Date

- 2024/07/02

- End Date

- 2024/07/05

- Event Details

-

Roadshow

Dates: 2 July 2024, 10:00 to 16:45 in Malaysia Time

Venue: Sofitel Kuala Lumpur DamansaraBootcamp

Dates: 3 to 5 July 2024Organizer: Topcon Positioning Asia (Malaysia) Sdn. Bhd., 3Dtech Solutions Sdn. Bhd.

- URL

- /content/topcon-pa/jp/en/events/2024/topcon-autodesk_roadshow-bootcamp_malaysia.html

- Target

- _self

- Start Date

- 2022/10/26

- End Date

- 2022/11/29

- Event Details

-

Venue : Webinars

Hosted by : Topcon / Autodesk

- URL

- /content/topcon-pa/jp/en/events/2022/10309.html

- Target

- _self